405nm

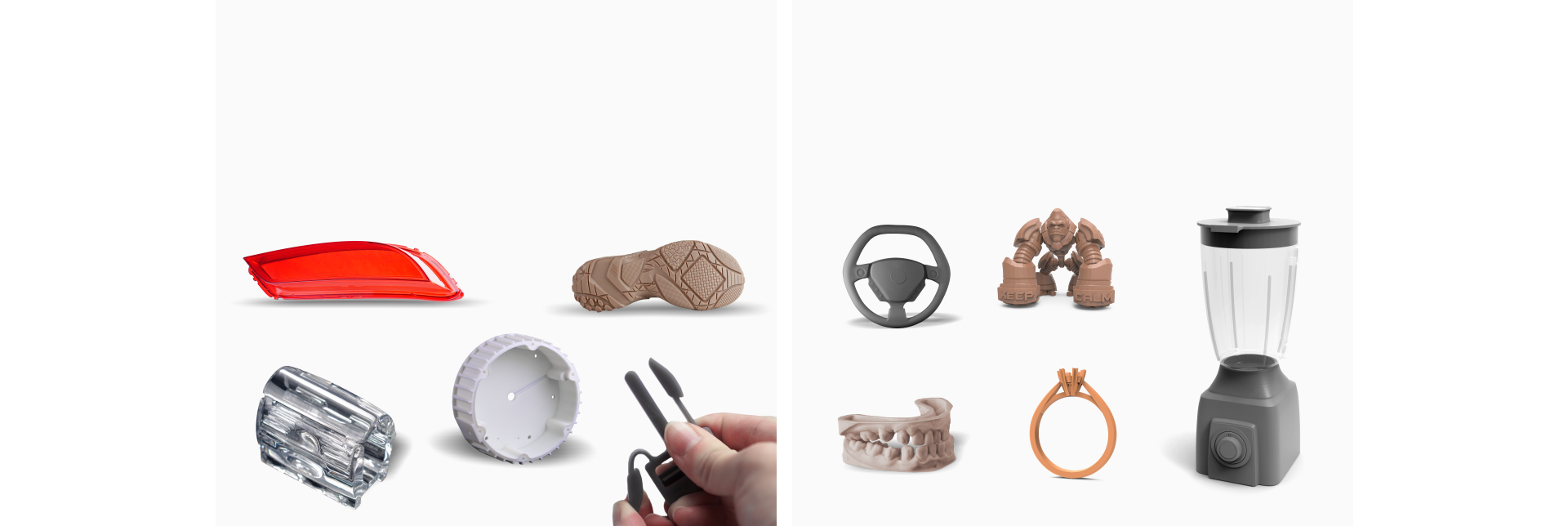

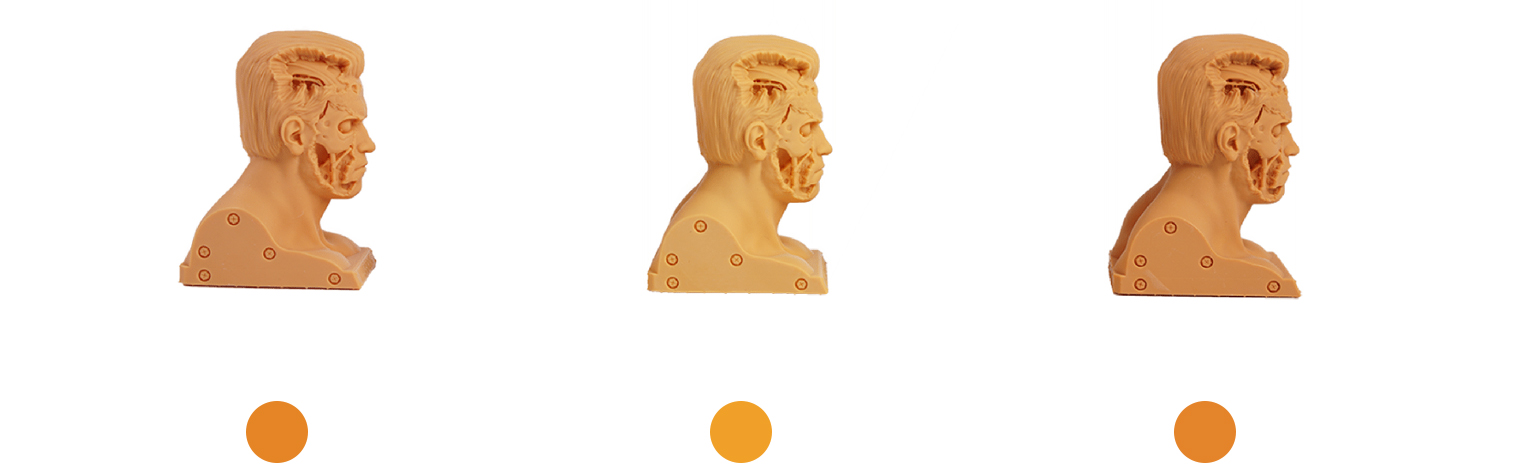

General Resin Series

Casting Resin Series

Engineering Resin Series

Shoe Resin Series

Dental Resin Series

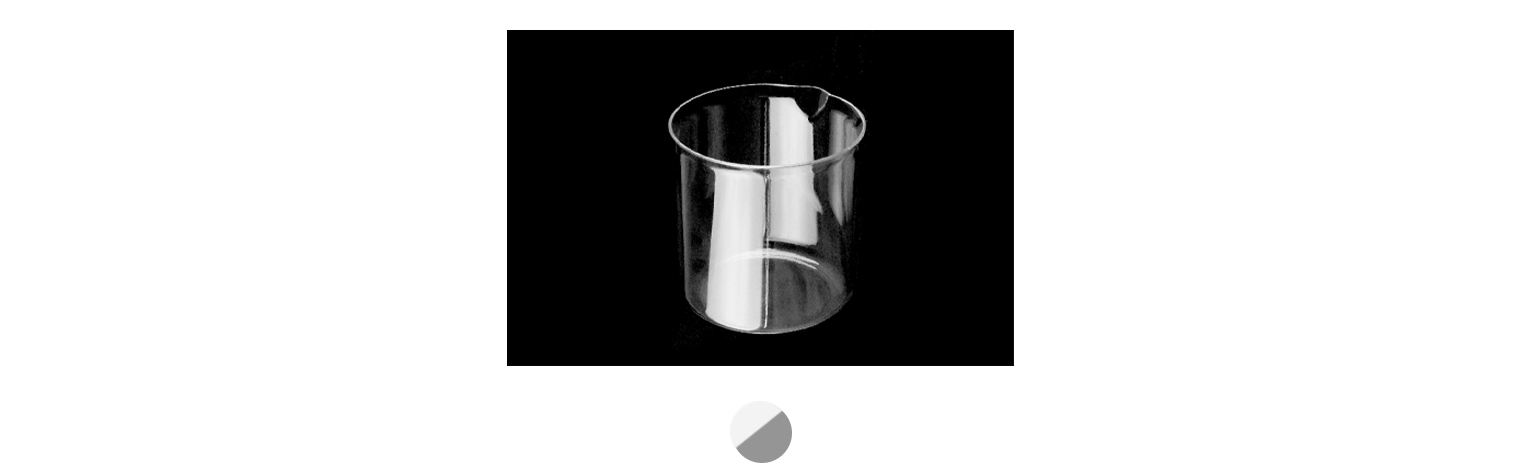

Clear Resin Series

355nm

General Resin Series

Casting Resin Series

Engineering Resin Series

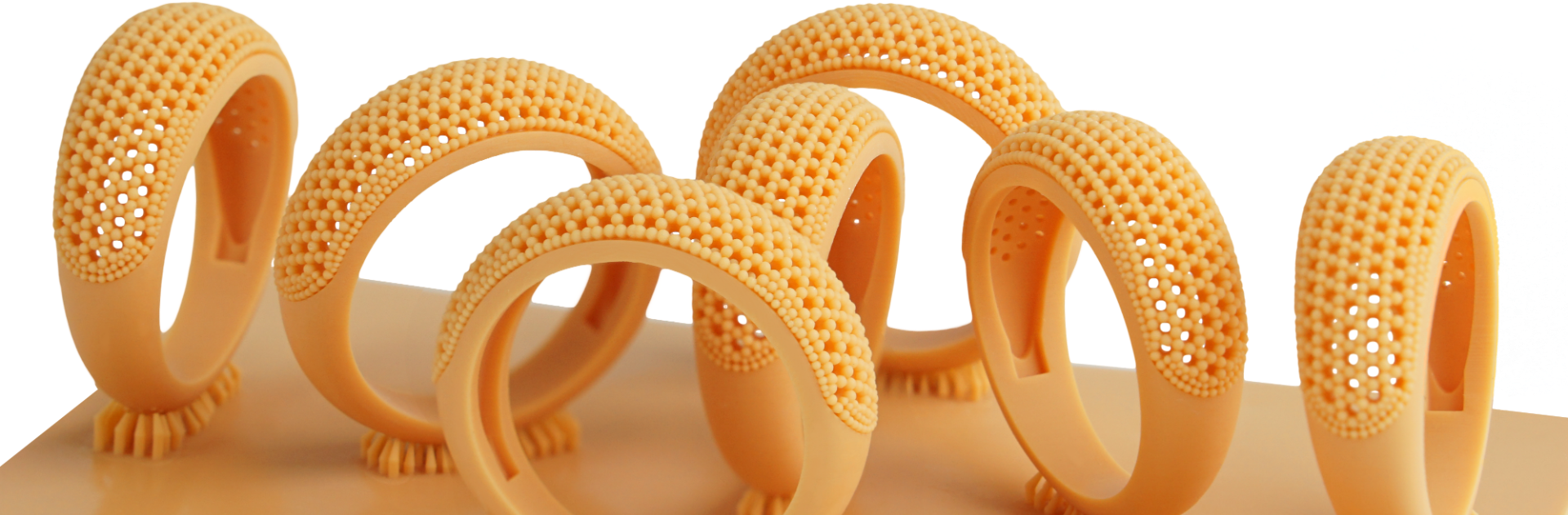

Jewelry&Sculpt Resin Series

Dental Resin Series

Clear Resin Series

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Hardness(Shore D)

Heat Deflection Temperature

Tensile Strength

Hardness(Shore D)

Hardness(Shore D)

Heat Deflection Temperature

Heat Deflection Temperature

Izod Impact(Notched)

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Modulus

Tensile Strength

Tensile Strength

Flexural Strength

Izod Impact(Notched)

Izod Impact(Notched)

Tensile Modulus

Flexural Modulus

Elongation at Break

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Strength

Hardness(Shore D)

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Modulus

Hardness(Shore D)

Heat Deflection Temperature

Heat Deflection Temperature

Izod Impact(Notched)

Izod Impact(Notched)

Elongation at Break

Elongation at Break

Flexural Modulus

Flexural Modulus

Tensile Strength

Tensile Strength

Tensile Modulus

Tensile Modulus

Flexural Strength

Flexural Strength

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Tensile Modulus

Flexural Strength

Izod Impact(Notched)

Flexural Modulus

Elongation at Break

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Hardness(Shore D)

Tensile Modulus

Flexural Strength

Izod Impact(Notched)

Flexural Modulus

Elongation at Break

Heat Deflection Temperature

General Resin Series

Casting Resin Series

Engineering Resin Series

Jewelry&Sculpt Resin Series

Dental Resin Series

Clear Resin Series

Flexural Modulus

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Tensile Modulus

Flexural Strength

Elongation at Break

Heat Deflection Temperature

Flexural Modulus

Izod Impact(Notched)

Hardness(Shore D)

For 355nm SLA 3D Printer | High quality, versatile and reliable

General Resin Series

Casting Resin Series

Engineering Resin Series

Shoe Resin Series

Dental Resin Series

Clear Resin Series

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

General Resin Series

Casting Resin Series

Engineering Resin Series

Shoe Resin Series

Dental Resin Series

Clear Resin Series

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact (Notched)

Heat Deflection Temperature

Hardness (Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Tensile Strength

Tensile Modulus

Izod Impact (Notched)

Hardness (Shore D)

Heat Deflection Temperature

Izod Impact (Notched)

Hardness (Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness (Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Izod Impact(Notched)

Hardness (Shore D)

Heat Deflection Temperature

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Izod Impact(Notched)

Hardness (Shore D)

Heat Deflection Temperature

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)