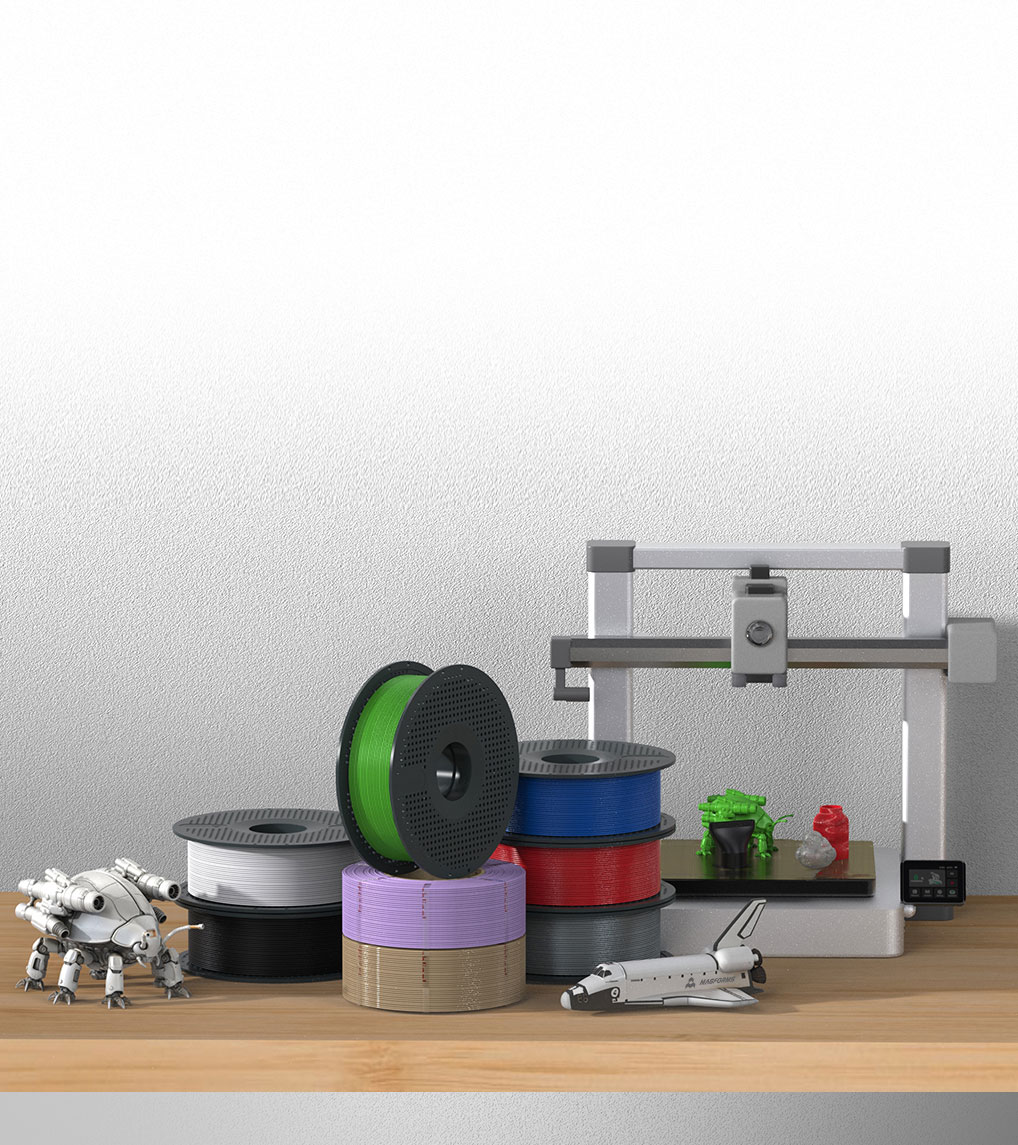

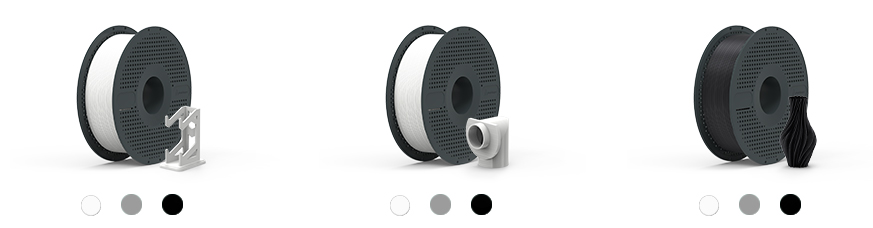

PLA Series

PETG Series

TPU Series

Functional Series

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Izod Impact(Notched)

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Modulus

Tensile Strength

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Izod Impact(Notched)

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore A)

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness(Shore A)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness(Shore D)

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness(Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

PLA Series

PETG Series

TPU Series

Functional Series