-

“Quality-Driven” Magforms P10: Accelerating Breakthroughs for High-End Jewelry Studios2025.10.09Read More >

“Quality-Driven” Magforms P10: Accelerating Breakthroughs for High-End Jewelry Studios2025.10.09Read More >

In the increasingly competitive manufacturing industry, product development speed and production stability are key determinants of a company's ability to stand out. However, for many companies relying on 3D printing technology for rapid prototyping and small-batch production, seasonal factors, especially the cold winter, pose significant challenges for resin. Low temperatures cause an increase in resin viscosity, which not only severely impacts print success rates but also leads to a decline in model surface quality, becoming a hidden culprit for project delays and cost overruns.

The Magforms P13 Pro 3D printer effectively solves this problem. Its dual heating system, combined with exceptional print speed and industrial-grade hardware precision, is helping numerous designers, engineers, and manufacturers achieve efficient, uninterrupted production year-round.

We interviewed James, a manager at a 3D printing service studio, to discuss how the P13 Pro translates its technical advantages into practical productivity, ensuring that printing jobs succeed the first time and maintain consistent surface quality, even in harsh environments.

For many studios and factories, winter means decreased efficiency and increased defect rates on the 3D printing production line. The root cause lies in the physical properties of resin materials: in cold environments, the molecular activity of resin slows down, intermolecular forces strengthen, leading to a sharp decrease in fluidity and an increase in viscosity.

"In the past, as soon as winter arrived, our workload increased," shared James. "High-viscosity resin struggled to spread evenly on the build platform, directly leading to model bottom detachment, surface blurring, rough details, or even overall deformation. We had to use warm water to evenly heat the resin, which consumed a lot of time." This common dilemma created an urgent need for a solution that could stabilize the environment and ensure printing consistency.

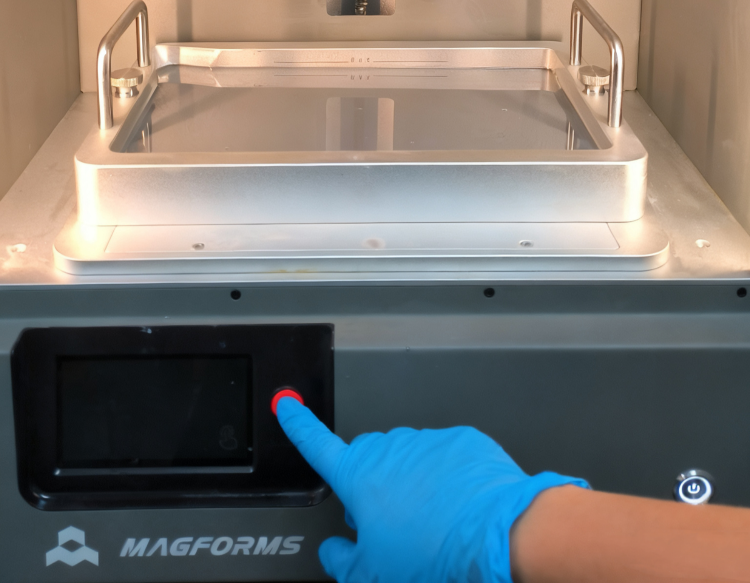

One of the core innovations of the Magforms P13 Pro is its dual heating system, designed specifically for low-temperature environments. This system cleverly addresses the resin viscosity issue at its source. Users simply need to tap the heating switch on the right side of the control screen, and the left and right heating modules located at the printer's rear quickly activate, heating the resin vat to the ideal temperature in a very short time. This process acts directly on the resin material, using thermal energy to weaken the van der Waals forces between resin molecules and increase molecular spacing, thereby significantly reducing viscosity and restoring its good fluidity.

"After turning on the dual heating function, the effect was immediate. It effectively prevented the most frustrating initial problem of bottom detachment while significantly improving the forming quality and detail representation of complex models. Now, regardless of the outdoor temperature, our P13 Pro runs stably indoors, as if we have an all-weather 'constant temperature production workshop'."

James, manager, a 3D printing service studio

The stability and high success rate of the P13 Pro are underpinned by the industrial-grade hardware used internally. The equipment employs P-grade dual linear guides with a running parallel accuracy of ±7μm and industrial-grade lead screws with an accuracy of ±5μm, ensuring smooth and stable Z-axis movement, effectively reducing layer lines, and mechanically enhancing the print success rate.

Furthermore, the uniform and efficient light source system is equipped with 91 imported high-collimation LED chips, ensuring uniform light intensity across the print area and sharp edge curing. An additional light source heat dissipation component provides strong protection for the stability of the equipment during long-term continuous operation and the lifespan of the light source.

"The hardware of this machine is very reliable. We used it to print many detailed samples without encountering any problems."

James, manager, a 3D printing service studio

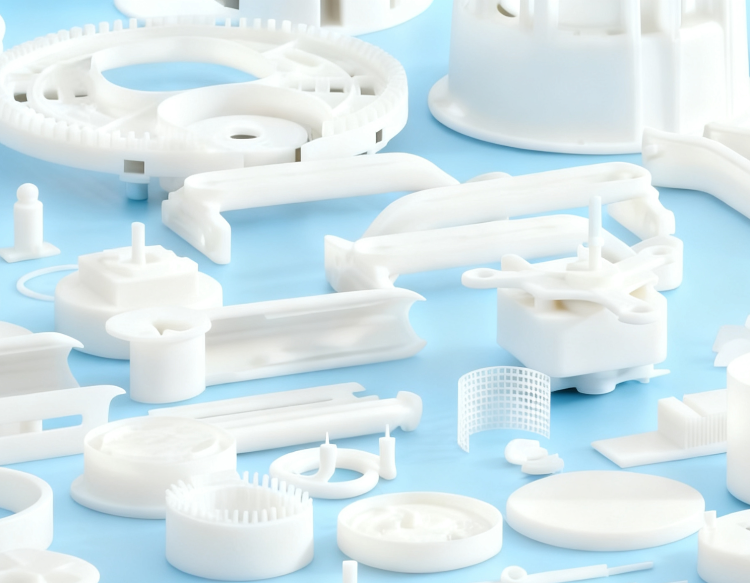

Beyond solving environmental challenges, the P13 Pro also excels in printing performance. The equipment boasts a large build volume of 302×162×380mm, sufficient for most prototyping needs.

Even more impressive is its combination of efficiency and precision. Printing a 300mm tall model at a 0.2mm layer thickness can be completed by the P13 Pro in as little as 3 hours and 15 minutes. This astonishing speed is thanks to its high light intensity output and exceptional operational stability, ensuring consistent surface quality even during high-speed printing.

In terms of precision, the P13 Pro is equally uncompromising. Its XY physical precision reaches 26μm, and through advanced grayscale management technology, it achieves a high resolution of 13μm, giving printed parts a delicate and smooth surface finish. Regarding dimensional control, the dimensional deviation for a 100mm sample is stably controlled within ±0.05mm, providing a solid guarantee for product assembly reliability.

The comprehensive performance advantages of the P13 Pro have been widely validated in the market. James pointed out that after his studio purchased the P13 Pro, they saw noticeable improvements in both printing accuracy and efficiency compared to their previous older machines.

"The P13 Pro is the most reliable partner in our workflow. It has solved our seasonal production headaches, and its speed and precision accelerate our product development cycle. Its stability and ease of use allow us to focus on the design itself, without worrying about the manufacturing process."

James, manager, a 3D printing service studio

In the increasingly competitive field of product design, a Shenzhen-based design studio has gained renown for its rapid, high-fidelity prototype production capabilities. Since its founding by Chief Designer Alex in 2020, the studio has experienced significant growth, evolving from serving startups to undertaking projects for international brands. This growth necessitated an upgrade of their core manufacturing capabilities.

Throughout the studio's expansion journey—from single projects to producing hundreds of precision prototypes weekly—the Magforms P10 printer has provided agile and reliable production support. "One of our studio's core competencies is having a reliable rapid prototyping system," Alex says. "My goal was to find technology that could match our creative pace and scale flexibly with project demands. In the early stages of a business, what you need most is equipment that can be seamlessly upgraded."

Today, the studio has fully integrated the Magforms P10 printing system into its product development workflow. Leveraging its large build volume, high precision, and excellent stability, the studio has enhanced efficiency, guaranteed delivery timelines, and significantly reduced overall costs.

In the increasingly competitive manufacturing industry, product development speed and production stability are key determinants of a company's ability to stand out. However, for many companies relying on 3D printing technology for rapid prototyping and small-batch production, seasonal factors, especially the cold winter, pose significant challenges for resin. Low temperatures cause an increase in resin viscosity, which not only severely impacts print success rates but also leads to a decline in model surface quality, becoming a hidden culprit for project delays and cost overruns.

The Magforms P13 Pro 3D printer effectively solves this problem. Its dual heating system, combined with exceptional print speed and industrial-grade hardware precision, is helping numerous designers, engineers, and manufacturers achieve efficient, uninterrupted production year-round.

We interviewed James, a manager at a 3D printing service studio, to discuss how the P13 Pro translates its technical advantages into practical productivity, ensuring that printing jobs succeed the first time and maintain consistent surface quality, even in harsh environments.