In the rapidly evolving modern manufacturing landscape, companies aiming to stay ahead must possess the ability to quickly and accurately translate top-tier ideas into high-quality physical objects. This demands innovation processes that combine both speed and an uncompromising attention to detail.

For eight years, Allen has managed rapid prototyping operations at the company's core prototype lab, which handles the majority of new product design, testing, and development. Allen likens the lab's operation to "a marathon run at a sprint's pace." His team needs to handle requests from dozens of product lines while consistently upholding a 24-hour delivery promise.

After integrating the Magforms SL800 into their equipment lineup, Allen was able to re-strategize print scheduling—incorporating many large-scale or batch projects that previously required overnight builds into the "daytime build" schedule. This significantly accelerated iteration cycles and boosted overall productivity. With its large build volume of 800*800*550mm and an intelligent, efficient software system, the SL800 is becoming a key tool for tackling challenging prototype projects.

Application Scenarios of the Magforms SL800 in the Enterprise

The lab handles diverse printing requests daily. To manage the continuous workflow, the lab is equipped with multiple FDM printers, several industrial-grade SLA machines, and desktop-grade equipment for small-batch production. Allen's team operates as an internal service center; they assess the requirements for each part, discuss with the requester, select the most suitable machine and material, handle setup, printing, post-processing, and deliver within 24 hours.

Despite the lab's already fast delivery speed, it sometimes wasn't fast enough for specific internal teams of architects and senior designers. "They operate at the intersection of imagination and engineering. When inspiration strikes, they need physical models for validation immediately. Their schedules aren't always neat and tidy," Allen says. The lab needed additional printing capacity—equipment that was easy to operate, cost-effective, fast, and capable of delivering high-quality parts in various materials. Following a recommendation from an engineer who had used Magforms equipment, they introduced the SL800.

"For me, the Magforms SL800 has become a must-have tool. A core part of my job is reviewing our equipment lineup and request types to identify capability gaps and fill them with the right technology. The SL800 fills the crucial role of 'large-format' and 'efficient batch processing' for us."

Allen, Additive Manufacturing Lead, a Technology Company

SL800: Reshaping Workflows with Large Build Volume and High Precision

In Allen's lab, they typically stop accepting same-day requests in the afternoon, then start the printers for overnight builds. The next morning, after completing deliveries, they look for new tasks suitable for daytime completion. Equipment capable of rapidly producing large parts can significantly enhance the productivity of the entire printer fleet.

"A prototype that previously needed to be split for printing on older equipment can now be produced as a single piece on the SL800. We can now handle these large projects during daytime builds, which was difficult before," Allen stated.

For a lab processing hundreds of parts weekly, enabling daytime builds means an exceptionally smooth workflow. Whether it's conceptual models in the early design stages or engineering samples for assembly verification, rapid iteration ensures ideas aren't lost in translation and allows for timely problem-solving for production lines.

"Completing critical design iterations within 24 hours is a core goal for us. Some answers are highly time-sensitive. We need to immediately understand why a part failed and quickly return with a revised design," Allen told us.

Beyond build speed, print quality and ease of use are equally crucial. The SL800's control network board, equipped with Panasonic servo motors, achieves a recoater positioning accuracy of ±8μm and a resin level positioning accuracy of ±0.03mm, ensuring dimensional accuracy regardless of model size.

"On some large flat panels, I've noticed better surface consistency compared to our previous equipment. Its control software uses a minimal spot size to perform multiple slow scans of contours, granting parts both excellent surface finish and uniform internal structural strength." Allen added.

Since integrating the SL800's array function into their workflow, Allen and his team have been able to take on more batch tasks, effectively boosting efficiency.

An engineer once requested 100 connectors for testing, requiring completion within two days. "Traditional software, duplicating 99 models with supports, would cause the computer to freeze and crash, leading to a very poor turnaround time," Allen said. The team used the SL800's array function: they added supports to just one model and instantly generated the remaining 99, completing the print in one day. "Delivering 100 high-quality parts in a single day—if we can do that, it's a significant efficiency gain," Allen emphasized.

While the SL800's hardware precision and array functions significantly boost team efficiency, its intelligent operating system is the core ensuring stable, long-term output.

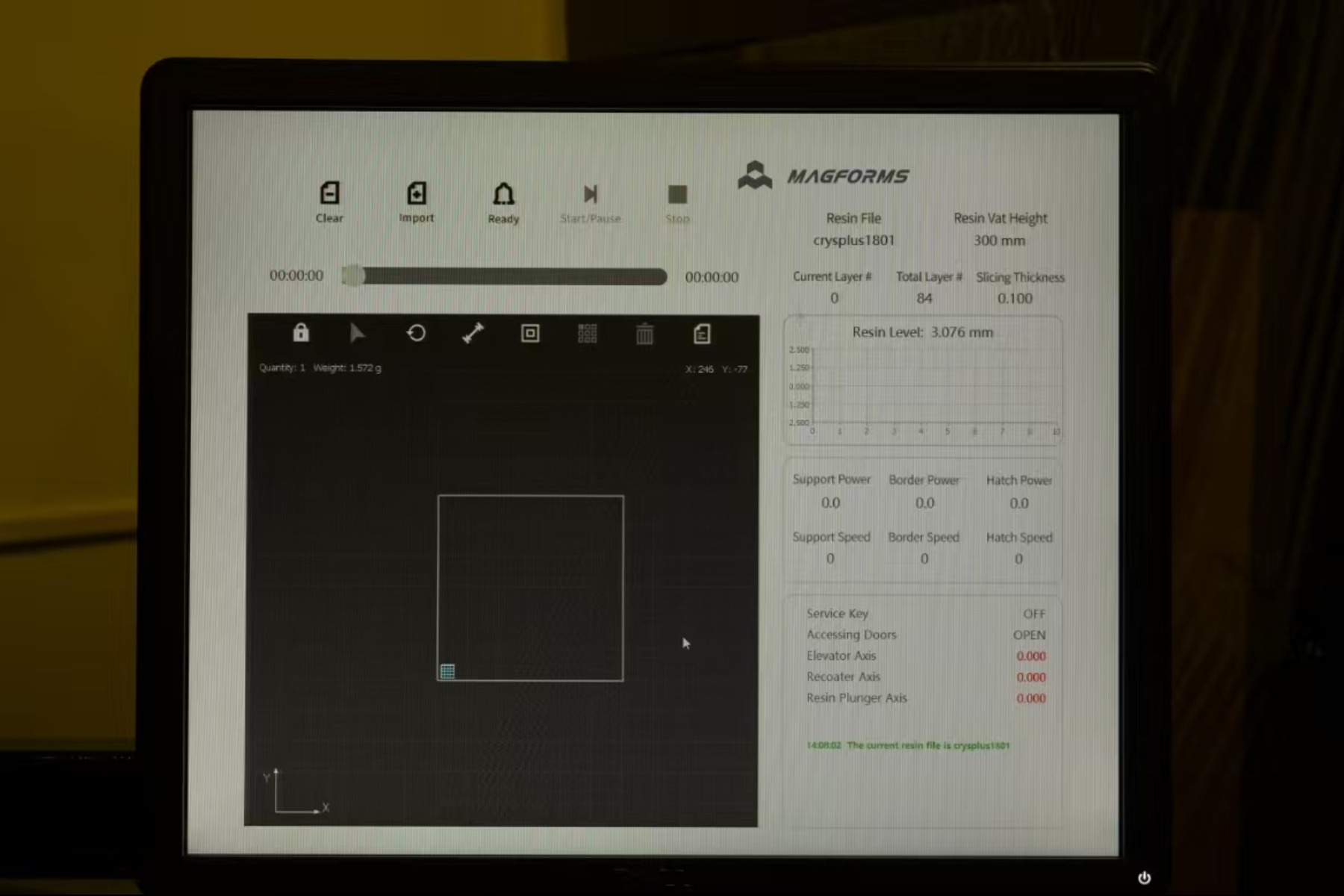

The magforms iBuild2.0 operating system powering the SL800, with its simple interface and smooth operation, eliminates the complexity and uncertainty often associated with operating industrial-grade equipment, allowing technicians to focus on the design itself.

Furthermore, its unique Learning Scanning System gives the machine self-optimizing capabilities. The system accumulates experience with each print, continuously refining parameters, making printing efficiency and quality "more efficient with use" over the long term, delivering continuous, lasting returns for the enterprise.

But print time isn't everything—pre-processing and post-processing time are also critical. The SL800's intelligent workflow, particularly its array function, drastically reduces pre-processing time, helping them convert concepts into deliverables faster.

"We can complete builds with multiple parts in three days, instead of over a week like before. In terms of building alone, the SL800 has proven its immense value."

Allen, Additive Manufacturing Lead, a Technology Company

Through its large build volume, micron-level printing precision, array functions, and continuously evolving intelligent systems, the Magforms SL800 opens new possibilities for enterprise product development workflows.

It makes the integrated manufacturing of large models routine and enables the rapid delivery of large-batch prototypes with ease. For a company sprinting on the path of innovation, the SL800 is more than just a tool for creating prototypes; it is a partner that accelerates the realization of ideas and builds core competitiveness. It allows the enterprise to maintain a leading sprint speed in the marathon toward the future.