Jack is the operator of a shoe factory in Guangzhou, responsible for overseeing the production process and managing customer orders. As competition in the industry intensifies, he has noticed that more and more peers are adopting 3D printing technology to optimize traditional shoemaking processes, aiming to break through the efficiency and precision bottlenecks in mold development.

As an entrepreneur focused on production management with limited knowledge of cutting-edge technology, Jack was initially cautious about introducing 3D printing. He admitted, "For me, the biggest concern about adopting 3D printing stems from my lack of a technical background. Could new equipment disrupt our existing production rhythm? If the printed molds fail to meet precision standards, could it affect product delivery, or even lead to customers demanding rework?"

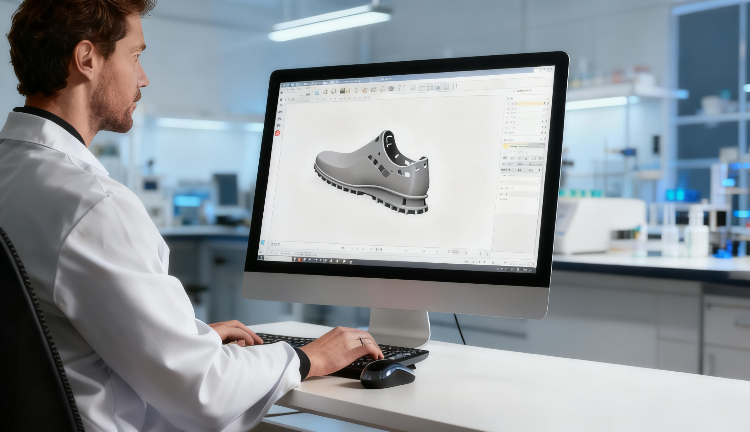

This article narrates the story of Jack's encounter with the Magforms P13 Pro device. It covers his motivation for deciding to transform, the practical challenges faced during the introduction of the large-format LCD 3D printing equipment, and how he found the confidence and motivation for a technological upgrade while remaining cautious about change.

"As managers, we must admit that the way manufacturing works today is vastly different from ten years ago. Change is the only constant."

Despite having solid reasons to drive technological upgrades, manufacturing businesses must still evaluate the risks when making decisions. When considering introducing 3D printing equipment like the Magforms P13 Pro, Jack focused mainly on the following points:

Financial Impact: Failed technological investments not only affect production schedules but also cause direct economic losses. Examples include molds being scrapped due to substandard printing accuracy, delayed delivery cycles, or waste of materials and labor hours due to unstable equipment. Jack said, "Failure always carries an economic cost. We need to calculate not just the cost of one machine, but also the time, materials, and reputational cost behind every failure."

Production Process Re-engineering: The longer a factory operates, the more solidified its processes become. Introducing any new equipment can disrupt the original production rhythm, requiring re-planning of manpower, scheduling, and even warehousing. "What we least want to see is the production process being disrupted. Originally, every step connected smoothly. Changing one process forces all others to readjust. This is a test for the entire team."

Becoming the Team's Technical Support: As the decision-maker, once new technology is introduced, one needs to shoulder the responsibility for internal promotion and troubleshooting. Jack noted, "If you yourself are not confident with the equipment, yet have to train employees and deal with various production issues, that psychological pressure is very real. This is also why many hesitate before technological upgrades."

These risks, while not meant to hinder progress, must be seriously considered in decision-making—not just from a technical angle, but also from the perspectives of business operation and people.

Jack's pragmatism and meticulousness make him a trusted figure among his peers. After learning the specific parameters of the Magforms P13 Pro, he chose the most direct verification method—driving from Guangzhou to Magforms for an on-site inspection.

On-site, he observed the entire printing process of the P13 Pro and conducted a detailed inspection of the printed shoe mold samples. The equipment boasts a large build volume of 302×162×380mm, capable of nesting and printing 12 shoe molds in one build. In terms of speed, printing a 300mm high model takes as little as 3 hours and 15 minutes. The P13 Pro offers high printing precision, strictly controlling the dimensional accuracy of a 100mm sample within 0.05mm, ensuring sharp and clear fine-grain textures, meeting the requirements for production verification. Jack made the purchase decision on the spot.

Jack's case demonstrates that for the footwear industry, selecting a 3D printing device that balances build size, efficiency, and precision is key to successfully achieving digital transformation. The Magforms P13 Pro is precisely such a product, born from addressing the industry's actual pain points. It is helping more and more manufacturing enterprises transform ideas into high-quality products with lower costs and greater speed.

Running a factory involves many milestone moments: from equipment installation and production line setup, to the first products rolling off the line and the first major customer order. However, as production becomes routine, daily management often solidifies, making it difficult to find the motivation to overhaul those processes that have "always been used completely." When sharing his transformation experience, Jack first posed a question: "When we consider introducing a new process or new equipment, what exactly is driving us?" He believes entrepreneurs choose to embrace new technology for four main reasons:

Learning and Growth: For many, revamping traditional processes used for decades is itself a challenge and an incentive. Jack stated, "For us, trying new things often comes with breakthroughs. When industry competition intensifies or we encounter insurmountable bottlenecks in certain processes, new technology brings new opportunities for growth and enhancement of professional capabilities. I've seen many peers reignite their team's technical passion after introducing 3D printing, even unlocking design possibilities that were previously unattainable."

Enhancing Competitiveness: Using advanced manufacturing technology as a standout feature can not only optimize production processes but also build customer trust and lead to more order opportunities. Jack pointed out, "Technologies like 3D printing can tangibly enhance our advantages in quoting and delivery times. When customers know you can produce samples and molds faster and more precisely, they are more willing to place orders with you. This translates into real reputation and competitiveness."

Achieving Design Freedom: 3D printing is inseparable from digital design. Many footwear developers have aesthetic or design backgrounds themselves. For those wishing to realize complex textures and intricate structures in physical production, 3D printing is that "missing piece." "Many people in our industry are very sensitive to shape, texture, and structure. Traditional mold manufacturing has too many limitations, whereas 3D printing combined with digital modeling allows us to truly translate creativity into physical objects without barriers," Jack added.

Solving Practical Bottlenecks: Every manufacturing enterprise faces various production challenges, such as overly long mold development cycles, difficulty realizing complex textures, and error accumulation across multiple stages. Jack explained, "This is precisely where technology can make a difference. For example, the traditional mold process involves over a dozen steps, is time-consuming and costly, while LCD 3D printing can directly replace key steps. This not only shortens the cycle and reduces costs but also lessens reliance on manual processes, making results more controllable."

Jack is the operator of a shoe factory in Guangzhou, responsible for overseeing the production process and managing customer orders. As competition in the industry intensifies, he has noticed that more and more peers are adopting 3D printing technology to optimize traditional shoemaking processes, aiming to break through the efficiency and precision bottlenecks in mold development.

As an entrepreneur focused on production management with limited knowledge of cutting-edge technology, Jack was initially cautious about introducing 3D printing. He admitted, "For me, the biggest concern about adopting 3D printing stems from my lack of a technical background. Could new equipment disrupt our existing production rhythm? If the printed molds fail to meet precision standards, could it affect product delivery, or even lead to customers demanding rework?"

This article narrates the story of Jack's encounter with the Magforms P13 Pro device. It covers his motivation for deciding to transform, the practical challenges faced during the introduction of the large-format LCD 3D printing equipment, and how he found the confidence and motivation for a technological upgrade while remaining cautious about change.

"As managers, we must admit that the way manufacturing works today is vastly different from ten years ago. Change is the only constant."

Despite having solid reasons to drive technological upgrades, manufacturing businesses must still evaluate the risks when making decisions. When considering introducing 3D printing equipment like the Magforms P13 Pro, Jack focused mainly on the following points:

Financial Impact: Failed technological investments not only affect production schedules but also cause direct economic losses. Examples include molds being scrapped due to substandard printing accuracy, delayed delivery cycles, or waste of materials and labor hours due to unstable equipment. Jack said, "Failure always carries an economic cost. We need to calculate not just the cost of one machine, but also the time, materials, and reputational cost behind every failure."

Production Process Re-engineering: The longer a factory operates, the more solidified its processes become. Introducing any new equipment can disrupt the original production rhythm, requiring re-planning of manpower, scheduling, and even warehousing. "What we least want to see is the production process being disrupted. Originally, every step connected smoothly. Changing one process forces all others to readjust. This is a test for the entire team."

Becoming the Team's Technical Support: As the decision-maker, once new technology is introduced, one needs to shoulder the responsibility for internal promotion and troubleshooting. Jack noted, "If you yourself are not confident with the equipment, yet have to train employees and deal with various production issues, that psychological pressure is very real. This is also why many hesitate before technological upgrades."

These risks, while not meant to hinder progress, must be seriously considered in decision-making—not just from a technical angle, but also from the perspectives of business operation and people.

In the increasingly competitive field of product design, a Shenzhen-based design studio has gained renown for its rapid, high-fidelity prototype production capabilities. Since its founding by Chief Designer Alex in 2020, the studio has experienced significant growth, evolving from serving startups to undertaking projects for international brands. This growth necessitated an upgrade of their core manufacturing capabilities.

Throughout the studio's expansion journey—from single projects to producing hundreds of precision prototypes weekly—the Magforms P10 printer has provided agile and reliable production support. "One of our studio's core competencies is having a reliable rapid prototyping system," Alex says. "My goal was to find technology that could match our creative pace and scale flexibly with project demands. In the early stages of a business, what you need most is equipment that can be seamlessly upgraded."

Today, the studio has fully integrated the Magforms P10 printing system into its product development workflow. Leveraging its large build volume, high precision, and excellent stability, the studio has enhanced efficiency, guaranteed delivery timelines, and significantly reduced overall costs.

Running a factory involves many milestone moments: from equipment installation and production line setup, to the first products rolling off the line and the first major customer order. However, as production becomes routine, daily management often solidifies, making it difficult to find the motivation to overhaul those processes that have "always been used completely." When sharing his transformation experience, Jack first posed a question: "When we consider introducing a new process or new equipment, what exactly is driving us?" He believes entrepreneurs choose to embrace new technology for four main reasons:

Learning and Growth: For many, revamping traditional processes used for decades is itself a challenge and an incentive. Jack stated, "For us, trying new things often comes with breakthroughs. When industry competition intensifies or we encounter insurmountable bottlenecks in certain processes, new technology brings new opportunities for growth and enhancement of professional capabilities. I've seen many peers reignite their team's technical passion after introducing 3D printing, even unlocking design possibilities that were previously unattainable."

Enhancing Competitiveness: Using advanced manufacturing technology as a standout feature can not only optimize production processes but also build customer trust and lead to more order opportunities. Jack pointed out, "Technologies like 3D printing can tangibly enhance our advantages in quoting and delivery times. When customers know you can produce samples and molds faster and more precisely, they are more willing to place orders with you. This translates into real reputation and competitiveness."

Achieving Design Freedom: 3D printing is inseparable from digital design. Many footwear developers have aesthetic or design backgrounds themselves. For those wishing to realize complex textures and intricate structures in physical production, 3D printing is that "missing piece." "Many people in our industry are very sensitive to shape, texture, and structure. Traditional mold manufacturing has too many limitations, whereas 3D printing combined with digital modeling allows us to truly translate creativity into physical objects without barriers," Jack added.

Solving Practical Bottlenecks: Every manufacturing enterprise faces various production challenges, such as overly long mold development cycles, difficulty realizing complex textures, and error accumulation across multiple stages. Jack explained, "This is precisely where technology can make a difference. For example, the traditional mold process involves over a dozen steps, is time-consuming and costly, while LCD 3D printing can directly replace key steps. This not only shortens the cycle and reduces costs but also lessens reliance on manual processes, making results more controllable."

Jack's pragmatism and meticulousness make him a trusted figure among his peers. After learning the specific parameters of the Magforms P13 Pro, he chose the most direct verification method—driving from Guangzhou to Magforms for an on-site inspection.

On-site, he observed the entire printing process of the P13 Pro and conducted a detailed inspection of the printed shoe mold samples. The equipment boasts a large build volume of 302×162×380mm, capable of nesting and printing 12 shoe molds in one build. In terms of speed, printing a 300mm high model takes as little as 3 hours and 15 minutes. The P13 Pro offers high printing precision, strictly controlling the dimensional accuracy of a 100mm sample within 0.05mm, ensuring sharp and clear fine-grain textures, meeting the requirements for production verification. Jack made the purchase decision on the spot.

Jack's case demonstrates that for the footwear industry, selecting a 3D printing device that balances build size, efficiency, and precision is key to successfully achieving digital transformation. The Magforms P13 Pro is precisely such a product, born from addressing the industry's actual pain points. It is helping more and more manufacturing enterprises transform ideas into high-quality products with lower costs and greater speed.