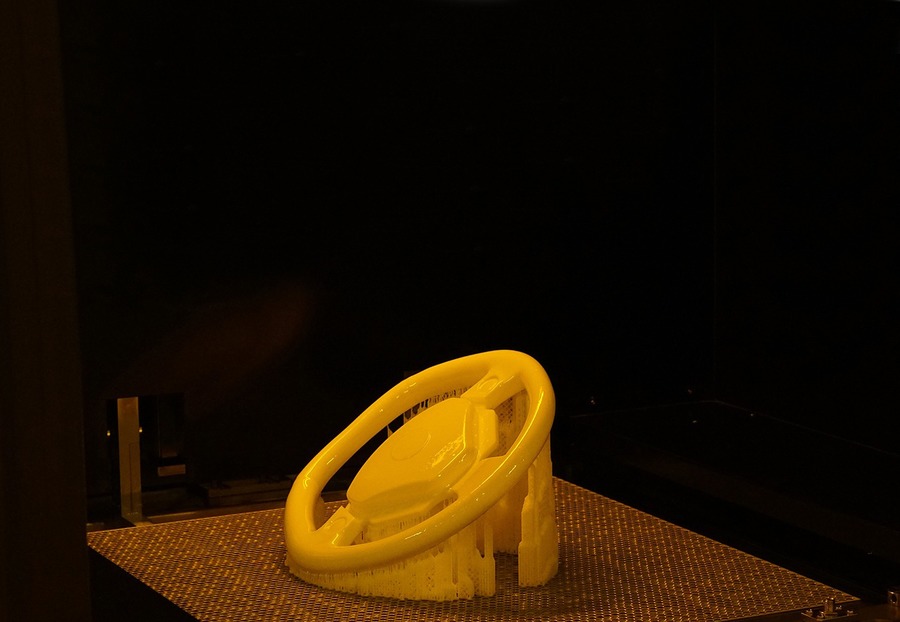

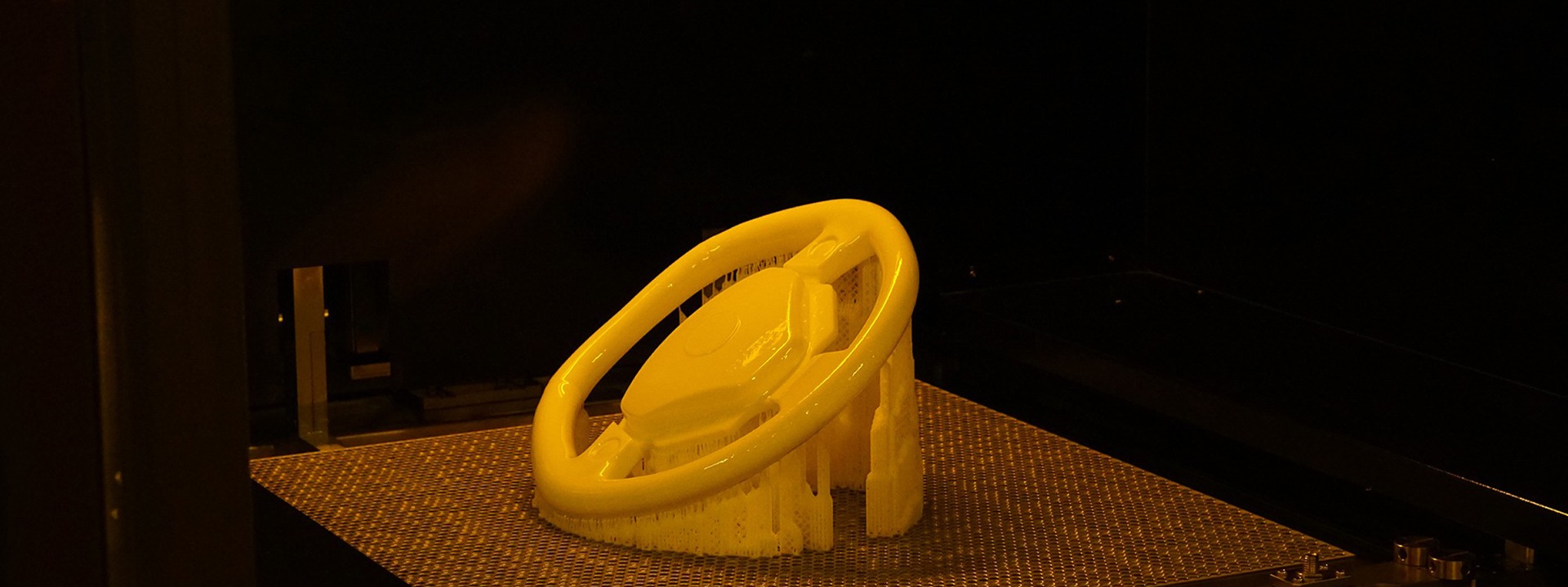

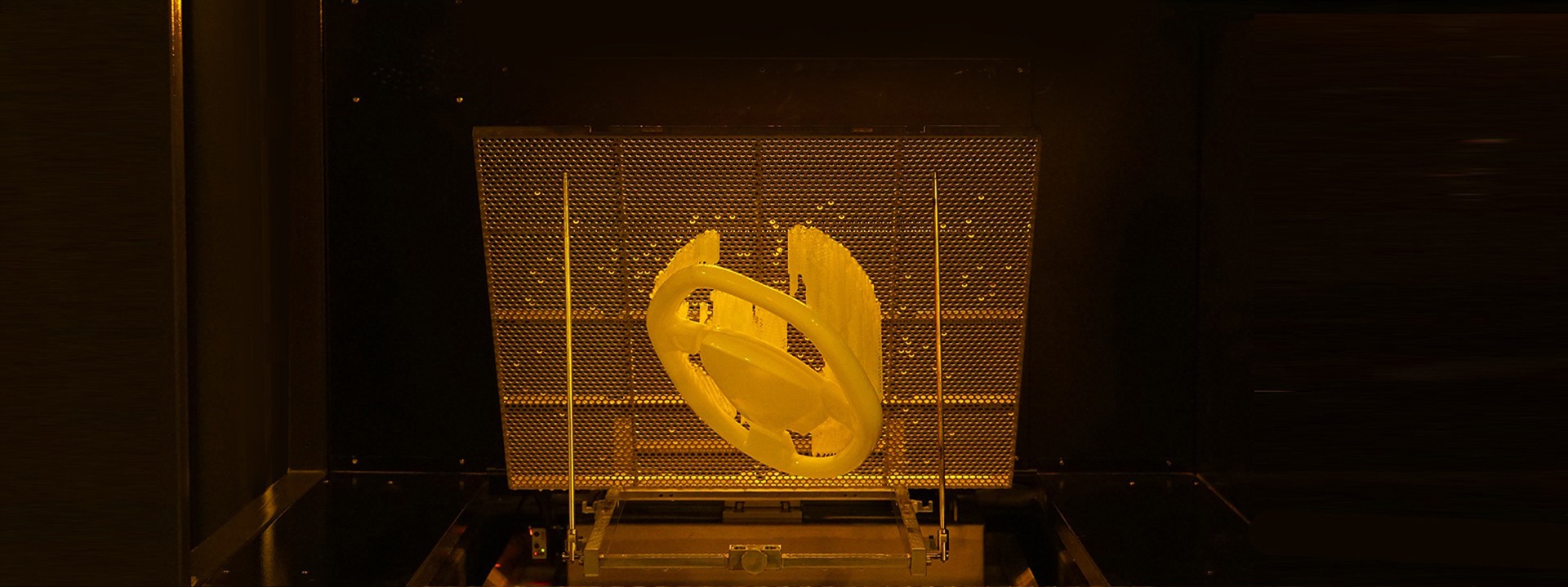

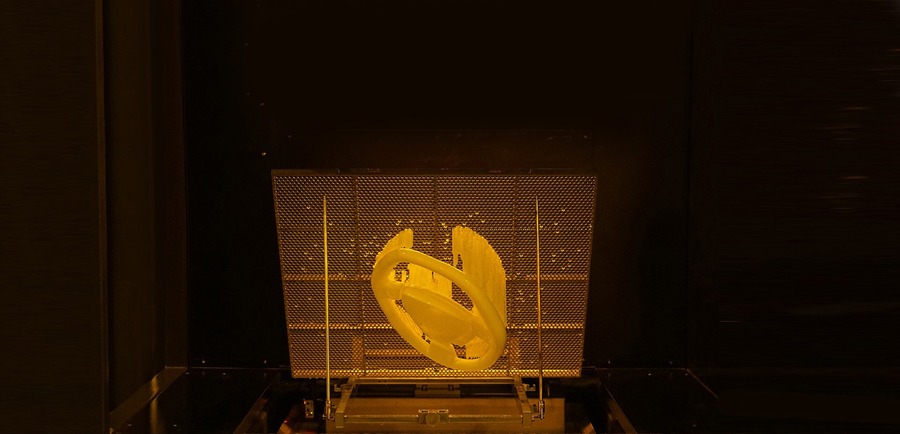

Performance de détail exceptionnelle, haute qualité constante

La plate-forme inversée permet à la résine de s'écouler plus rapidement

30% - 50% plus rapide que la technologie SLA traditionnelle

Removable resin vat series

Fixed resin vat series

Max Build Volume

Accuracy

Slicing Thickness

Machine Size

Weight

Resin Vat Capacity

Max Build Volume

Slicing Thickness

Max Build Volume

Machine Size

Resin Vat Capacity

Weight

Machine Size

Weight

Resin Vat Capacity

Slicing Thickness

Operating Environment

Beam Size

Accuracy

Accuracy

Beam Size

Beam Size

Operating Environment

Operating Environment

Max Build Volume

Accuracy

Beam Size

Slicing Thickness

Operating Environment

Machine Size

Resin Vat Capacity

Weight

Max Build Volume

Accuracy

Slicing Thickness

Machine Size

Weight

Resin Vat Capacity

Max Build Volume

Slicing Thickness

Resin Vat Capacity

Weight

Machine Size

Operating Environment

Beam Size

Accuracy

Beam Size

Operating Environment

General Resin Series

Engineering Resin Series

Shoe Resin Series

Dental Resin Series

Clear Resin Series

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact (Notched)

Heat Deflection Temperature

Hardness (Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Tensile Strength

Tensile Modulus

Izod Impact (Notched)

Hardness (Shore D)

Heat Deflection Temperature

Izod Impact (Notched)

Hardness (Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Strength

Flexural Strength

Flexural Modulus

Tensile Modulus

Elongation at Break

Izod Impact(Notched)

Heat Deflection Temperature

Hardness (Shore D)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Tensile Strength

Tensile Modulus

Izod Impact(Notched)

Hardness (Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Hardness (Shore D)

Heat Deflection Temperature

Elongation at Break

Flexural Modulus

Flexural Strength

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Izod Impact(Notched)

Hardness (Shore D)

Heat Deflection Temperature

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)

Tensile Strength

Tensile Modulus

Flexural Strength

Flexural Modulus

Elongation at Break

Hardness(Shore D)

Heat Deflection Temperature

Izod Impact(Notched)