2025.11.10

Magforms,Lab300,3D Printing

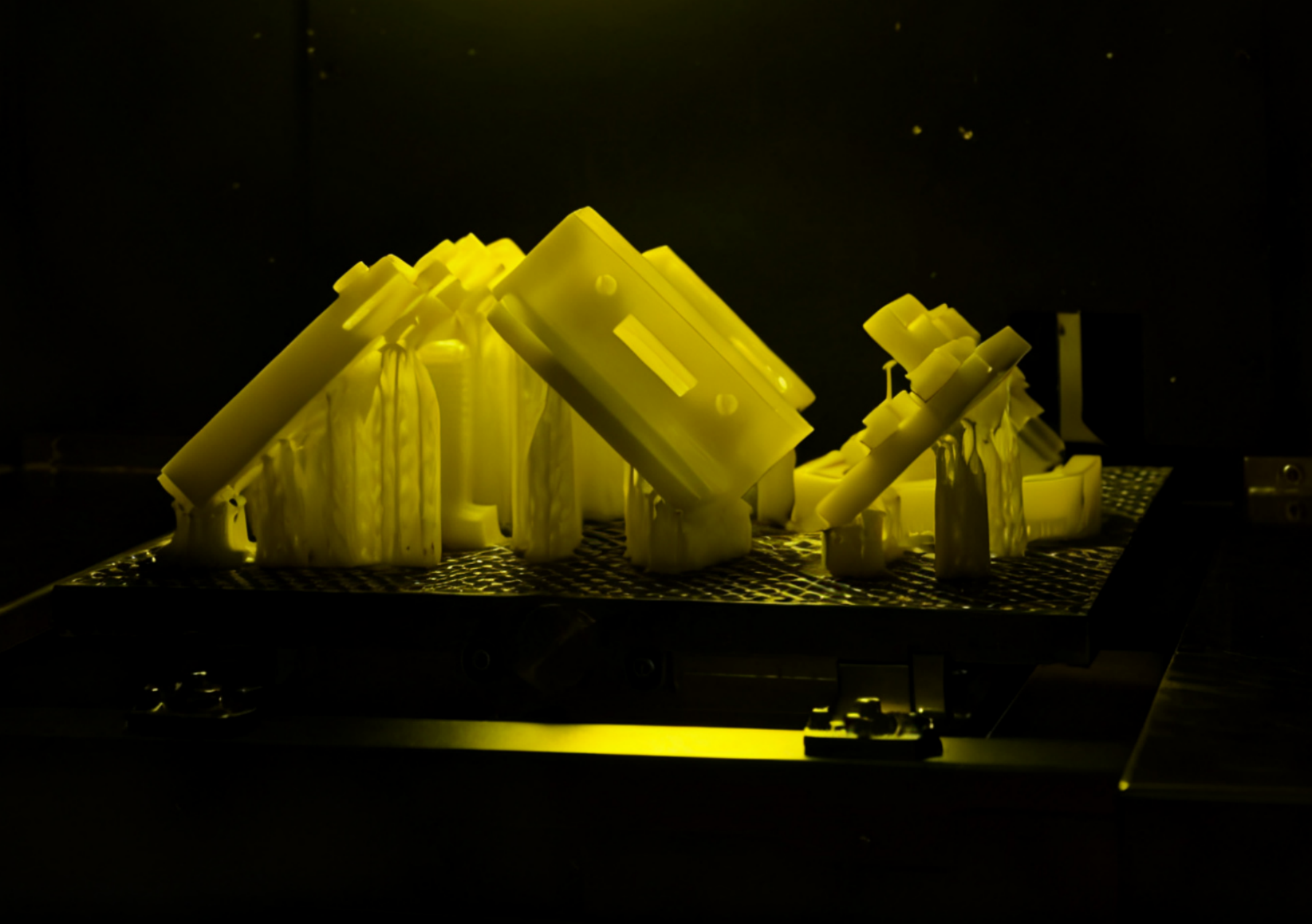

Since the proliferation of desktop 3D printers, users have faced a difficult trade-off among build volume, stability, and cost. Today, the Magforms Lab300 SLA 3D printer, with its unique positioning, offers users an exceptional balance of print accuracy, equipment stability, and spatial convenience, empowering small and medium-sized studios and enterprises to reliably step into industrial-grade manufacturing.

The Lab300 is not merely a larger version. It integrates a 355nm laser source, Intelligent Variable Spot Size technology, and a series of user-friendly designs, enhancing print success rates and detail representation from the ground up, while significantly reducing the costs associated with iterative testing and material management.

Magforms engineers, with deep insight into the pain points of small and medium-sized studios, developed the Lab300. This device incorporates industrial-grade core components and intelligent design within a compact body, specifically designed for applications requiring high precision and high stability, such as prototype development, small-batch production, and precision casting.

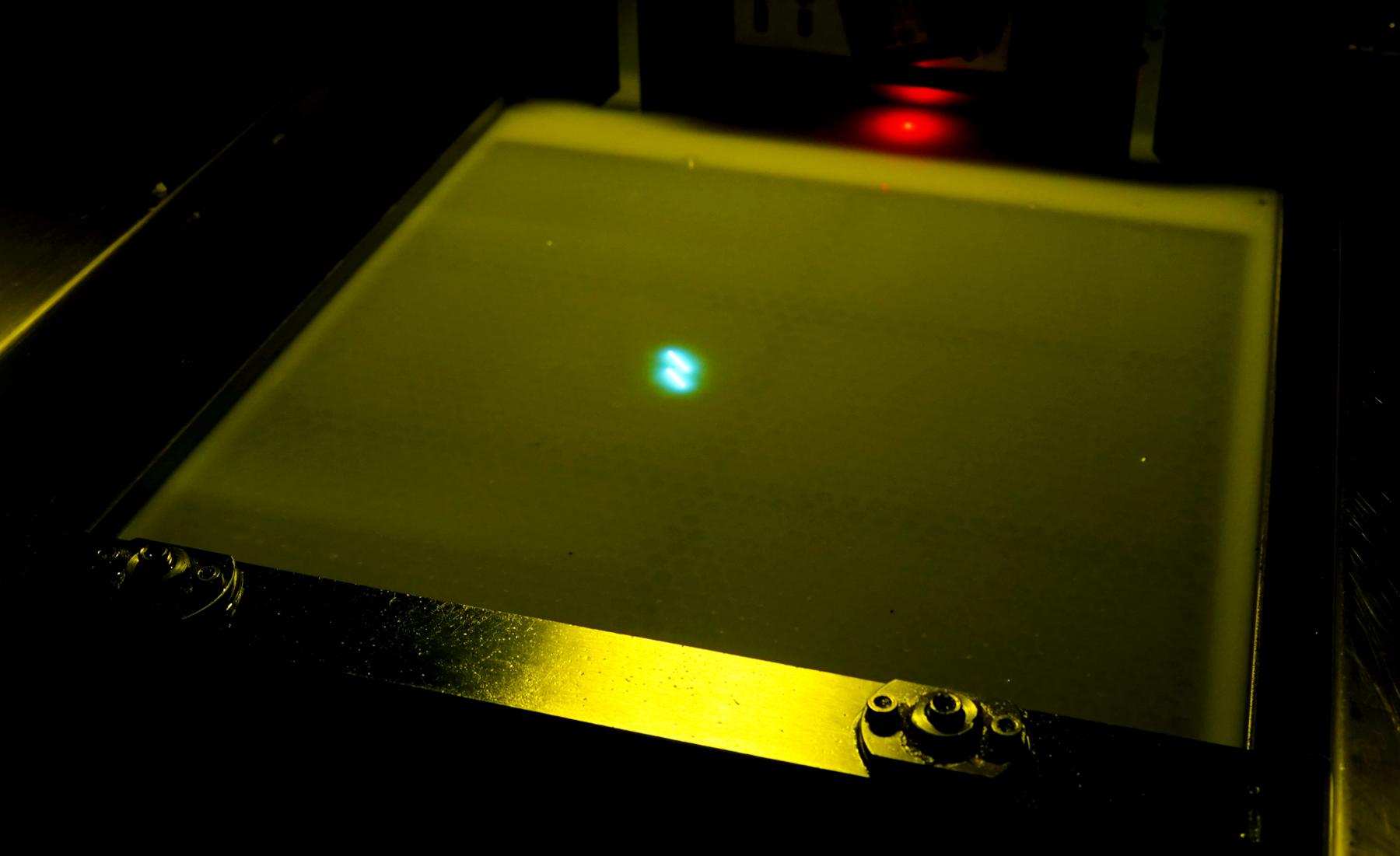

1、Intelligent Variable Spot Size Technology: A larger spot size of 0.5-0.6mm enables fast filling, while a finer spot size of 0.18-0.2mm is used for detailed contour processing. This significantly improves efficiency while guaranteeing precision.

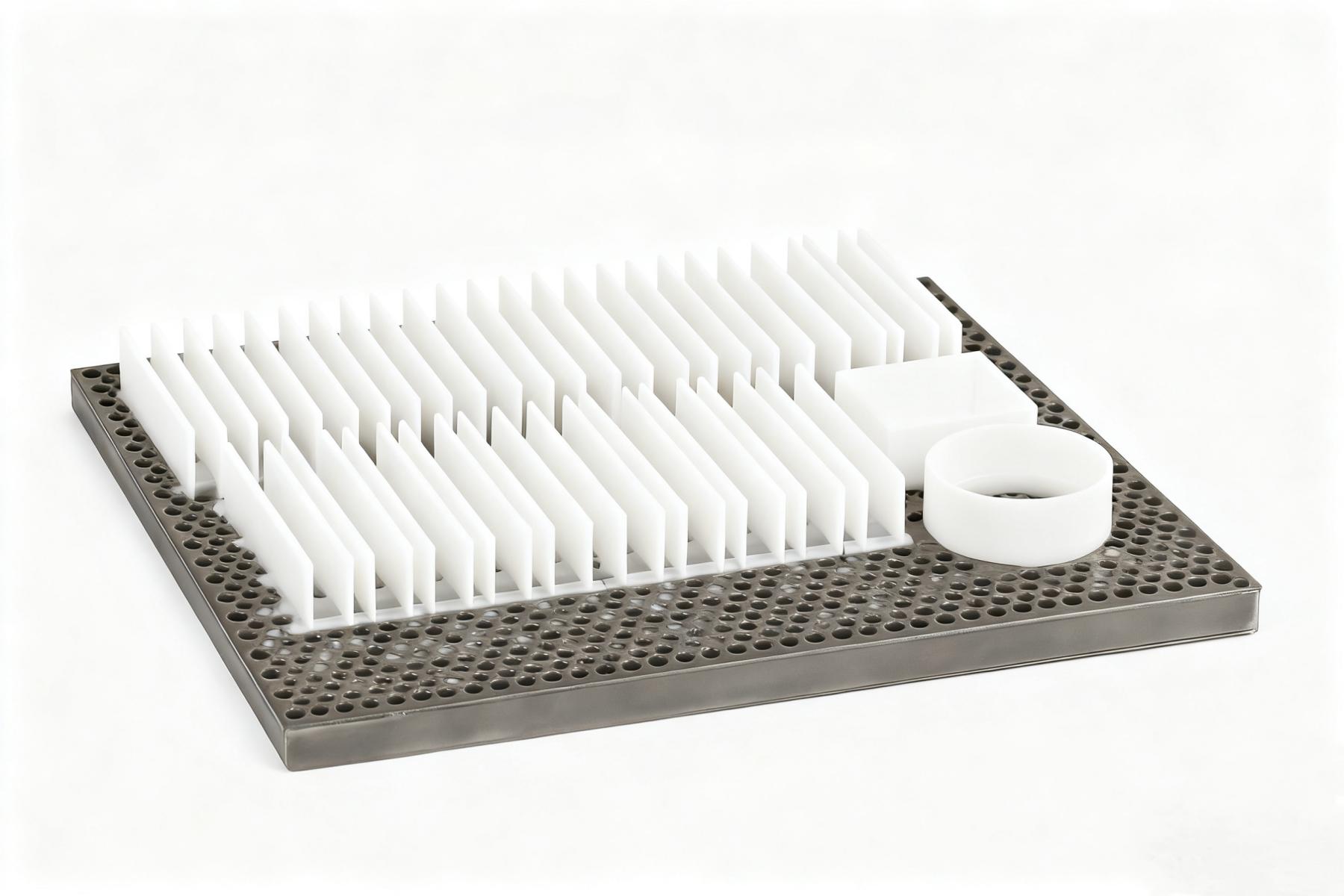

2、Removable Resin Vat: Supports dedicating separate vats to different materials, enabling rapid material switching. This saves substantial cleaning time and labor costs, enhancing workflow efficiency.

3、Small-Volume Resin Vat Design: Significantly reduces the amount of resin required per test print, avoiding waste of precious materials during the experimental phase, making material testing and iteration more cost-effective.

4、Integrated Tank Lifting Adjustment: Its liquid level response speed surpasses traditional floating level sensors. It allows for quick adjustment of the resin height during the printing process, preventing print failures caused by an unstable resin surface at the source, thereby further improving success rates and material utilization.

5、Core Components: Utilizes Panasonic servo motors and HIWIN linear guides, ensuring high precision and long-term operational reliability from the core.

Magforms Lab300: Excellence in Both Form and Function

Feature / Device | Desktop LCD Printer | Magforms Lab300 | Traditional Industrial SLA Printer

|

Characteristics | Small size low entry cost easy operation | Small size high precision high stability | Large size, high precision high stability

|

Light Source | 405nm Light Source | 355nm Laser Source | 355nm Laser Source |

Price | Lower | Medium | Higher |

Application Scenarios | Individuals, Small/Medium Studios | Small/Medium Studios Enterprises | Small/Medium Studios Enterprises |

Thanks to its 355nm laser source, the Lab300 can be compatible with professional resin materials that have lower curing shrinkage rates. This significantly reduces the risk of internal stress and warping deformation during the printing process, thereby ensuring the dimensional stability and surface integrity of printed parts.

Excellent Design, Simplifying Complexity

Get Started with Magforms Lab300

From precision engineering prototypes to dental models and jewelry casting, the Magforms Lab300 enables small and medium-sized teams to acquire stable and precise industrial-grade printing capabilities without the burden of expensive industrial equipment. Its convenient size allows you to unlock more manufacturing possibilities within limited space.

Explore more information about the Magforms Lab300 or contact us for a quote and a tailored solution for your needs.