2025.10.27

Magforms, SL800, 3D Printing

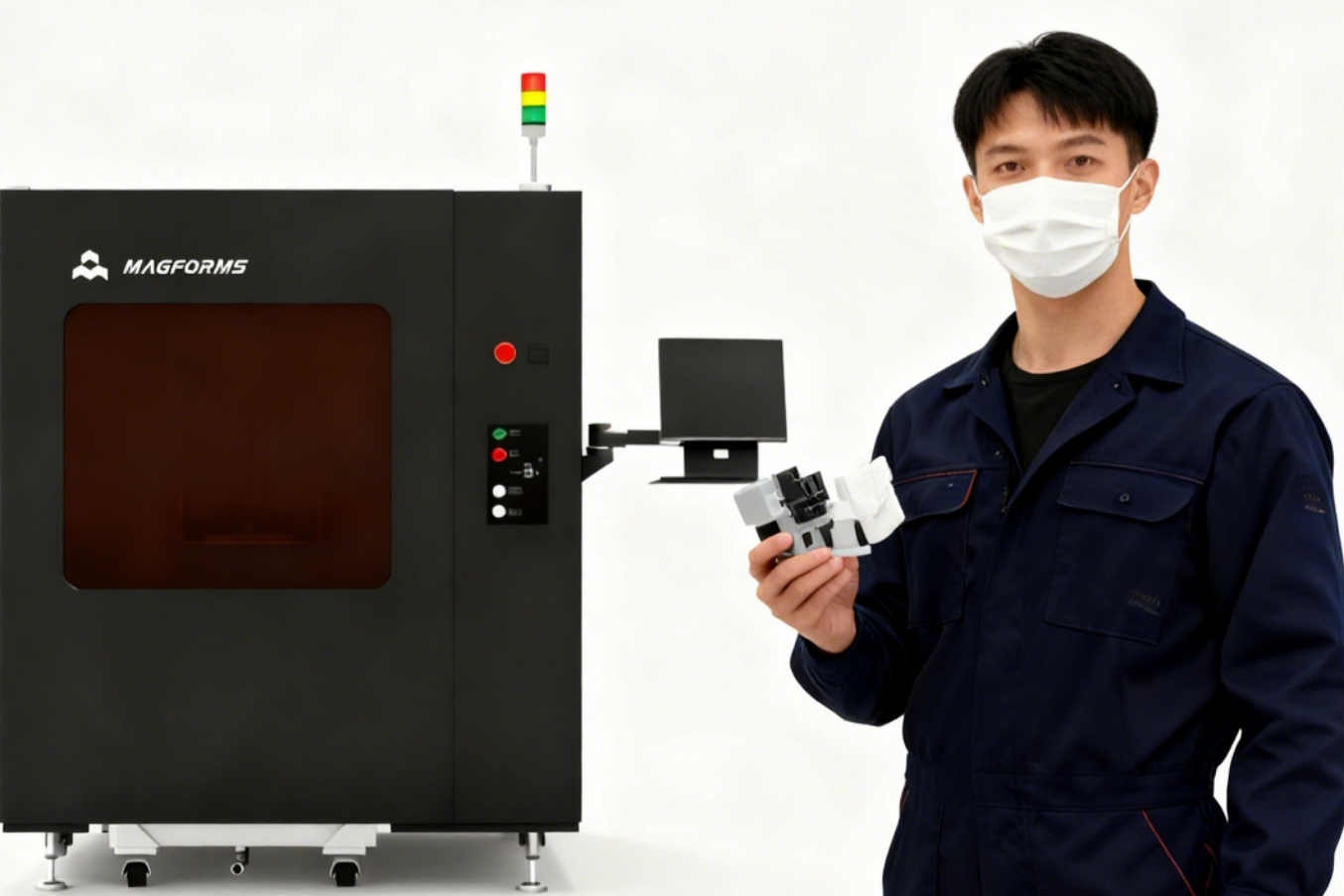

n the fields of industrial manufacturing and product development, the demand for large, high-precision prototypes and end-use parts is increasingly growing. Magforms' industrial large-scale SLA 3D printer, the SL800, is dedicated to providing professional users with a powerful solution that breaks through the limitations of traditional manufacturing, helping them transform creative designs into exceptional physical entities.

Extra-Large Build Volume, Breaking Production Constraints

With its massive build volume of 800×800×550mm, the SL800 redefines the scale boundaries of industrial-grade additive manufacturing. This design makes it possible to produce large functional parts in a single run and integrate multiple components for consolidated printing, effectively solving the splicing challenges faced by traditional equipment when handling large-sized workpieces. Even when printing tall structures or batch nesting multiple parts, the equipment maintains excellent forming stability, significantly improving the efficiency and reliability of large-scale manufacturing.

Industrial-Grade Core Components, Ensuring Continuous and Stable Output

To meet the stringent durability requirements of industrialized continuous production, the core components of the SL800 are sourced from internationally renowned brands. The equipment is equipped with an AOC laser that offers stable output and a long service life, ensuring sustained and stable energy output even under high-intensity 24/7 operation. Simultaneously, it features a high-performance German Scanlab galvanometer system, achieving high-speed scanning and precise positioning across the large build area, guaranteeing uniform and reliable print quality in every corner. The entire machine adopts a structural design with a 2mm thickened steel plate shell and a precision granite platform, providing solid mechanical support for long-term high-load operation and effectively suppressing vibration and thermal deformation.

Exceptional Precision and Stable Structure, Meeting Stringent Industrial Standards

The SL800 strictly adheres to industrial manufacturing standards in terms of printing precision: when the dimension L ≤ 100mm, the accuracy reaches ±0.15mm; when L > 100mm, the accuracy is controlled within ±0.15% × L. This level of precision ensures the equipment can clearly reproduce the fine structural features, sharp edges, and precise mating surfaces of complex industrial components. Combined with its robust mechanical structure and optimized control system, the SL800 maintains consistent printing quality during long-term continuous operation, perfectly adapting to various industrial application scenarios ranging from functional prototype verification to direct end-use part manufacturing.