-

“Quality-Driven” Magforms P10: Accelerating Breakthroughs for High-End Jewelry Studios2025.10.29Read More >

“Quality-Driven” Magforms P10: Accelerating Breakthroughs for High-End Jewelry Studios2025.10.29Read More >

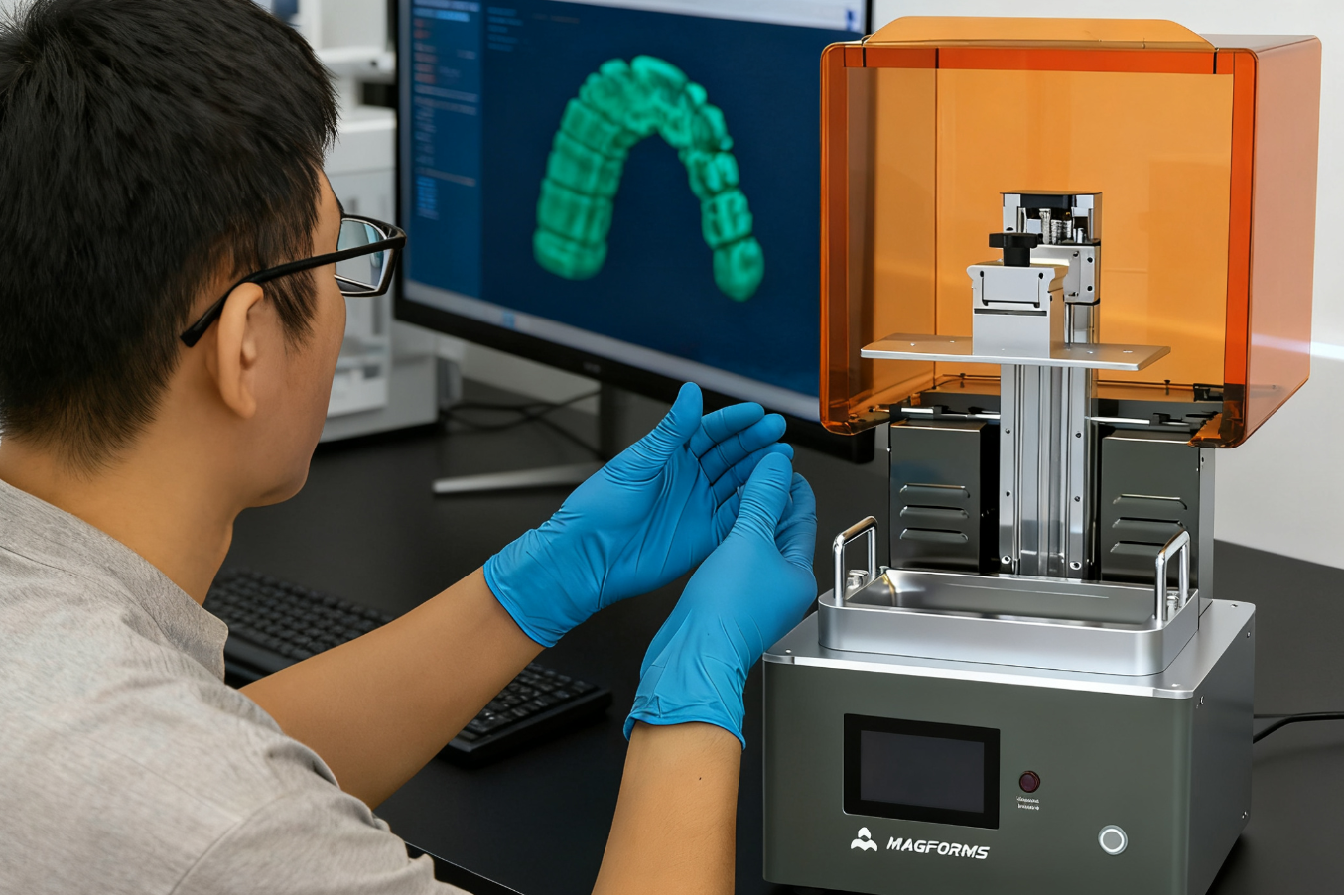

Andrew has been deeply involved in the dental model manufacturing industry for many years. His core business involves transforming digital models of patients' mouths, obtained by dentists through intraoral scanners, into physical dental models using advanced 3D printing technology. These precise models serve as a critical foundation for dentists to create custom medical devices such as aligners and retainers for their patients.

Since the printed results are directly used for medical diagnosis and treatment, the accuracy requirements for the printing equipment are extremely stringent—dimensional errors of the models must be consistently controlled within 0.06 millimeters. This standard places exceptionally high demands on the stability of the light source during the printing process, requiring uniform light intensity across the entire printing area.

In the early stages of his venture, the 3D printers Andrew used struggled to meet professional standards in terms of accuracy and stability. Printing results often contained deviations, which not only affected subsequent aligner production but also led to dual losses in time and materials due to repeated printing. This challenge was resolved after he introduced the Magforms P10 3D printer. This equipment enabled the successful single-print production of dental models, significantly reducing the rework rate and markedly improving production efficiency while lowering operational costs.

The Technical Foundation of Precision and Stability

The core advantage of the P10 stems from its self-developed array of industrial-grade light source system. This innovative technology significantly improves light uniformity by effectively reducing the light source divergence angle, ensuring that the light intensity across the entire printing platform remains stable within the optimal range of 3.2~3.5 mW/cm².

It is worth noting that the P10 also innovatively incorporates an industrial-grade high-precision dual-guide rail system with a travel parallel accuracy of up to 5 micrometers. These two core technologies work synergistically to ensure that the printing accuracy can be stably controlled within 0.05 millimeters, not only meeting but exceeding the industry standards for dental model manufacturing.

"The most significant change brought by the P10 lies in its exceptional stability," Andrew shared. "In the past, we often had to reprint entire batches of models due to minor accuracy deviations. Now, that's a thing of the past. This reliability allows us to make firmer commitments to our clients regarding delivery timelines."

Intelligent Upgrade of the Workflow

Thanks to the P10's build platform and stable, rapid printing capability, Andrew's workflow has achieved a qualitative leap.

"We can now arrange for multiple patients' dental models to be completed in a single print job. Scan data received in the afternoon can be printed the same evening, and post-processed and shipped the next morning. This efficiency boost allows us to calmly handle various urgent requests from dental clinics," Andrew explained.

For a dental model printing studio, the stability of the printing equipment holds more value than pure printing speed alone. Andrew added, "Some printers may claim fast speeds on paper, but frequent print failures and subsequent adjustments actually reduce overall efficiency. The stable output of the P10 enables us to achieve more precise production planning without worrying about unexpected interruptions."

Extended Value of the Digital Workflow

The digital workflow also brings many advantages that are difficult to achieve with traditional methods.

"The storage and retrieval of digital files have become exceptionally convenient. When a dental clinic needs to remake an aligner for a patient, we simply retrieve the corresponding digital file to quickly print a new model, avoiding the inconvenience of the patient having to visit the clinic again for physical impressions. This saves valuable time for both the clinic and the patient," Andrew emphasized.

This advantage is particularly prominent when dealing with special situations. Andrew recalled, "Once, a patient lost their retainer while traveling and couldn't find a local solution. After the patient's dentist contacted us, we immediately retrieved the data, printed the model, and produced a new retainer, shipping it to the patient overnight. The digital process made this cross-regional collaboration possible, greatly enhancing the added value of our service."

Want to learn more about how high-precision 3D printing can optimize your dental model manufacturing process? Contact us to get detailed technical specifications and success cases for the Magforms P10, and discover how it can empower your business.